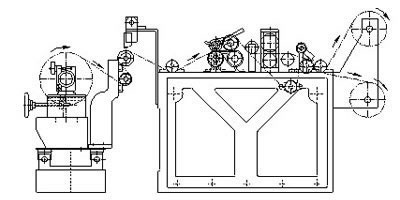

This FQ-WA series horizontal slitter rewinder offers the maximum slitting speed of 160m/min. The most prominent characteristics of this universal type product lies in its extremely convenient operation, smooth material transfer, easy material stretching, as well as the large working space.

Detailed Data| Model | |||

| Max. Width of Substrate | 700mm | 1100mm | 1300mm |

| Max. Unwind Diameter | Φ600mm | Φ600mm | Φ600mm |

| Slitting Width Range | 50-700mm | 50-1100mm | 50-1300mm |

| Max. Rewind Diameter | Φ380mm | Φ380mm | Φ380mm |

| Diameter of Roll Core of Substrate | Φ76mm | Φ76mm | Φ76mm |

| Max. Mechanical Speed | 180m/min | 180m/min | 180m/min |

| Max. Slitting Speed | 160m/min | 160m/min | 160m/min |

| Deviation-rectifying Error | ±0.5mm | ±0.5mm | ±0.5mm |

| Total Power of Machine | 3.1kW | 3.9kW | 3.9kW |

| Machine Weight | 1800kg | 2000kg | 2200kg |

| Overall Dimension | 2300*1900*12 00mm | 2300*2300*12 00mm | 2300*2500*12 00mm |

Performance

1. The main body of our horizontal slitter rewinder is designed with variable frequency.

2. The stand-alone control cabinet is flexible and convenient to operate.

3. The unwind unit adopts the automatic deviation rectifying system. The photoelectric eye is able to track the edge or line.

4. In addition, the unwind unit takes advantage of the air shaft and the magnetic powder brake. Tension can be controlled automatically.

5. The rewind unit also makes use of the air shaft, which can be equipped with the cam shaft. A magnetic powder clutch is used for rewinding.

6. Beyond that, our horizontal slitter rewinder is designed with a useful device for blowing off the scrap edge.

7. The length of the transferred material is counted automatically.

8. The pressure roller for rewinding allows the material roll to be rather neat.

9. The circular-knife slitting device is optional.

Characteristics

1. The raw material can be assembled or unassembled in use of the pneumatic-opening type shaftless clamping and hydraulic lifting structure.

2. The differential air shaft allows our horizontal slitter rewinder to be adapted to slitting the materials of uneven thickness.

3. The main transmission and rewind unit are respectively driven by two vector frequency inverters. The rewind tension is automatically controlled by the programmable logic controller by adoption of the digitized taper method. The parameters and the variation of rewind diameter can be set upon request.

4. The unwind tension takes advantage of the automatic tension control system, which enables the unwind tension to keep constant. Also, this system can realize the taper tension control according to the technical requirements. The LPC photoelectric automatic alignment system imported from Japanese MITSUHASHI can track edge or line automatically. Therefore, it can ensure the correct position of the material transferred.

5. Inside our vertical slitter rewinder, the electrical control system is controlled by the PLC system. A touch screen is utilized to set the slitting parameters, based on the specific requirements for the slitting process. The LCD screen can display the working status. Additionally, the control system can offer multiple functions, such as soft start, fixed-length count, and more. Therefore, our horizontal slitting and rewinding machine is extremely convenient to operate.