This AZJ-A gravure printing machine has begun to be sold by our company since inception. It is considered the most beneficial machine with its maximum printing speed up to 130m/min. Over the past decade, we have never stopped improving both service and product quality. Our product has been strictly tested before entering the overseas market. If customers require it, we will dispatch our staff for on-site commissioning and maintenance to guarantee the normal use of the machine.

Our company can provide either the standard type or three-motor type gravure printing machine. This machine is the major product of our company. It is ideal for the multicolor, one-off, and continuous printing of various materials, such as BOPP, PET, PVC, PE, aluminum foil, paper rolls, and the film rolls featuring outstanding printing performance. Moreover, this product gives wide applications in all kinds of high-end prints.

Technical Parameters| Model | |||

| Effective Print Width | 600mm | 800mm | 1000mm |

| Max. Width of Substrate | 650mm | 850mm | 1050mm |

| Max. Printing Speed | 130m/min | 130m/min | 130m/min |

| Max. Speed of Machine | 150m/min | 150m/min | 150m/min |

| Max. Unwind-Rewind Diameter | 600mm | 600mm | 600mm |

| Internal Diameter of Roll Core of Substrate | 76mm | 76mm | 76mm |

| Diameter of Gravure Cylinder | 105-380mm | 105-380mm | 105-380mm |

| Register Accuracy | ±0.1mm | ±0.1mm | ±0.1mm |

| Tension Range | 3-25kg | 3-25kg | 3-25kg |

| Heating Power of Drying Oven | 72kW | 96kW | 120kW |

| Total Power | 109kW | 136kW | 160.5kW |

| Weight | 18000kg | 20000kg | 22000kg |

| Overall Dimension (L*W*H) | 13300*3200*2500mm | 13300*3400*2500mm | 13300*3600*2500mm |

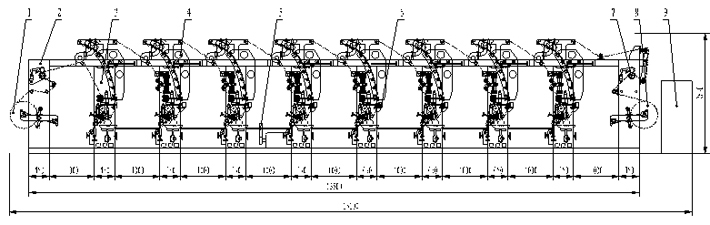

Partial Picture of the Machine

Partial Picture of the Machine1. All control units of the automatic register system are independently configured with the microprocessor, which can correct the deviation of color register fast and accurately.

2. The main body of our rotogravure printing machine features variable frequency. In other words, its speed can be adjusted.

3. The unwind tension is controlled by the automatic tension controller and the magnetic powder brake.

4. The rewinding process takes advantage of the torque motor. In addition, this intaglio printing press is equipped with the double-station dancer roll.

5. Our product also comes with the closed type drying oven, the stand-alone air supply and heating system, as well as the constant temperature control system.

6. The pneumatic pressing system and the pneumatic ink scraping (wipe) system.

7. The pneumatic and automatic ink circulating system.

8. The air shaft is used for loading and unloading of paper or plastic roll during unwinding and rewinding.

9. The gravure printing machine can display both linear velocity and meter readouts.

10. Our device allows the gravure to be mounted without the help of any shaft.

11. Beyond that, this product can be optionally mounted with the web video inspection system.